MECHANICAL ENGINEERING

INDUSTRIAL

DESIGNER

3D CAD Design, Fabrication & Management

With over 14 years of progressive experience, helping companies grow by integrating innovative design and manufacturing techniques, safety practices, effective R&D and marketing.

With over 14 years of progressive experience, helping companies grow by integrating innovative design and manufacturing techniques, safety practices, effective R&D and marketing.

Technical Skills

Skills acquired from experience and training

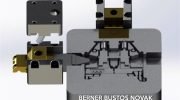

Mechanical

Design

Turning ideas into fabricable products, from small parts to large-scale industrial plants.

- CAD Design

- Parametric Modeling

- R&D

- Mechanical Parts

- Machinery

- Structural Design

- Hydronic Systems

- Piping Systems & Spools

- Pump/Equipment Skids

- Aluminum Framing

- Acoustic Panels

- Machine Guarding

- Rigging

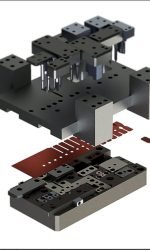

Industrial

Design

Combining art, business, and engineering across the stages of a product’s lifecycle.

- Sketching

- Concept CAD Modeling

- Prototyping

- Ergonomics

- Electromechanics

- Parametric Modeling

- Fabrication & Assembly

- Product Documentation

- Marketing & Sales

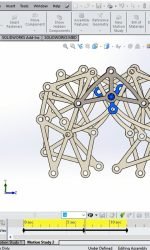

3D CAD / CG

Graphics

Bringing concepts to life with 3D renderings and animation, for control GUI & visualization.

- Detailed 3D Modeling:

- Texturing

- Rigging

- Lighting

- Rendering

- Motion Graphics

- Floor Plan Graphics

- Aerial View Renderings

- BAS Graphics

- Human-Machine Interface (HMI)

- UI/UX Design

- Image Editing

- Audio Editing

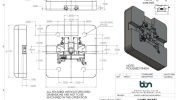

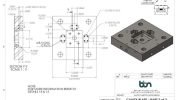

Technical

Documentation

Preparation of engineering drawings, diagrams, and submittals for projects.

- Drafting

- GD&T

- Detail Drawings (2D/3D)

- Fabrication Drawings

- Assembly Drawings

- BOM’s

- P&ID’s

- Wiring Diagrams

- Mechanical Specifications

- Submittals:

- Mechanical

- Instrumentation

- Electrical

- Instruction Manuals

Standards

& Codes

Design and documentation based on, or in compliance with the main industry rules.

- ANSI

- ASME

- ASHRAE

- ASTM

- NEMA

Metal Working

& Fabrication

Certified machinist apprentice, experienced in manual and computerized fabrication.

- Precision Machining:

- Drilling

- Milling

- Turning

- Grinding

- Metrology

- Benchworking

- Hand & Power Tools

- Metallurgy

- Heat Treatments

- Metal Cutting, Forming & Joining

- Assembly

- Jigs & Fixtures

- Injection Molds

- Tool & Dies

- 3D Printing (PLA & ABS)

- CNC, G-code, CAM

Management

& Planning

Assessment of business and project needs to determine an effective course of action.

- Product lifecycle management (PLM)

- Front-end loading (FEL)

- Eng. documentation control (EDC)

- Configuration management (CM)

- GANTT charts

- Flowcharts

- Preventive & corrective actions

- Procurements

- Work scheduling

- Fabrication planning

- Hiring & training

Supervision &

Occupational Safety

Experienced in fabrication supervision and ensuring a safe work environment.

- Inspection

- Monitoring

- OHSA

- WHMIS

- Material Handling Safety

- Lockout/Tagout

- Ladder Safety

- Applied Trade Safety Practices

- Personal Protective Equipment (PPE)

- Standard First Aid, CPR and AED

Mechanical Design

Turning ideas into fabricable products, from small parts to industrial plants.

- CAD Design

- Parametric Modeling

- R&D

- Mechanical Parts

- Machinery

- Structural Design

- Hydronic Systems

- Piping Systems & Spools

- Pump/Equipment Skids

- Aluminum Framing

- Acoustic Panels

- Machine Guarding

- Rigging

Industrial Design

Combining art, business, and engineering through the stages of a product’s lifecycle.

- Sketching

- Concept CAD Modeling

- Prototyping

- Ergonomics

- Electromechanics

- Parametric Modeling

- Fabrication & Assembly

- Product Documentation

- Marketing & Sales

3D CAD / CG Graphics

Bringing concepts to life, with 3D rendering and animation, for control GUI & visualization.

- Detailed 3D Modeling:

- Texturing

- Rigging

- Lighting

- Rendering

- Motion Graphics

- Floor Plan Graphics

- Aerial View Renderings

- BAS Graphics

- Human-Machine Interface (HMI)

- UI/UX Design

- Image Editing

- Audio Editing

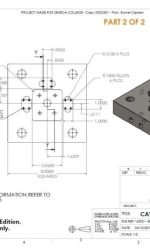

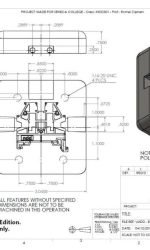

Technical Documentation

Preparation of engineering drawings, diagrams, and submittals.

- Drafting

- GD&T

- Detail Drawings (2D/3D)

- Fabrication Drawings

- Assembly Drawings

- BOM’s

- P&ID’s

- Wiring Diagrams

- Mechanical Specifications

- Submittals:

- Mechanical

- Instrumentation

- Electrical

- Instruction Manuals

Codes & Standards

Design and documentation based on, or in compliance with the industry’s main standards.

- ANSI

- ASME

- ASHRAE

- ASTM

- NEMA

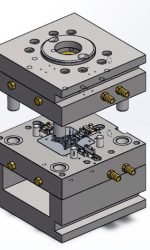

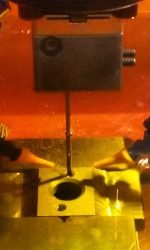

Metal working & Fabrication

Certified machinist apprentice, experienced in hand and computerized fabrication.

- Precision Machining:

- Drilling

- Milling

- Turning

- Grinding

- Metrology

- Benchworking

- Hand & Power Tools

- Metallurgy

- Heat Treatments

- Metal Cutting, Forming & Joining

- Assembly

- Jigs & Fixtures

- Injection Molds

- Tool & Dies

- 3D Printing (PLA & ABS)

- CNC, G-code, CAM

Management & Planning

Design and documentation based on, or in compliance with the industry’s main standards.

- Product lifecycle management

- Front-end loading (FEL)

- Eng. documentation control (EDC)

- Configuration management (CM)

- GANTT charts

- Flowcharts

- Preventive & corrective actions

- Procurements

- Work scheduling

- Fabrication planning

- Hiring & training

Supervision & Occupational Safety

Experience overseeing fabrication and ensuring a safe work environment

- Inspection

- Monitoring

- OHSA

- WHMIS

- Material Handling Safety

- Lockout/Tagout

- Ladder Safety

- Applied Trade Safety Practices

- Personal Protective Equipment (PPE)

- Standard First Aid, CPR and AED

Work Experience

Relevant experience from the last 10 years

7

▲ 2019-2021

7-7

Continual Energy Inc. | TO CA

Mechanical Design & Fabrication Manager

• Co-designed and managed/supervised the fabrication of 4 centrifugal compressor test stands. These unique projects required extensive research, prototyping, design and fabrication of innovative mechanisms, pipe spools, parts, and a combination of materials. that strengthened the company’s R&D capabilities and paved the way for the development of its new line of products.

• Developed and proposed a Product Lifecycle Management (PLM) Package, with a Front-end-loading (FEL) approach, that included Engineering Documentation Control (EDC), Configuration Management (CM), marketing and sales strategies. With over 300 folders and document templates, GANTT charts, flowcharts I designed and tailored to strategically manage all the stages of the company’s products in development.

6

▲ 2017-2019 ▲

6-7

Continual Energy Inc. | TO, CA

CAD / Mechanical Designer

• Co-led the mechanical design and fabrication of the company’s first two large-scale projects, an energy efficient hydronic/HVAC system for a plastic injection company in Mexico and a test chiller and load simulation plant for the R&D labs of the world-leading manufacturer of centrifugal compressors in the U.S., both projects were designed / fabricated in Canada as modules that required minimum effort for the installation on-site.

I developed the CAD models, mechanical engineering drawings, performed design and fabrication R&D, planned and supervised fabrication, cross-border shipping, and on-site installation (remotely and in-person) and trained engineering personnel in Mexico.

The success of these projects ensured future expansion and R&D projects with the clients over the next 3+ years and laid the foundation for the creation of the new R&D team.

5

2016-2017 ▲

5-7

Continual Energy Inc. | TO CA

CAD / BAS Graphics Designer

• Improved the creation of BAS control graphics (GUI) by developing a drag & drop system with high quality rendered, animated and customizable 2D/3D components with pre-programmed logic (in DGlux5), the new GUI required less time and training to develop, and its effectiveness played a key role in project sales.

• Developed a library of 3D CAD mechanical, instrumentation, and electrical components and had a central role in the standardization of technical drawings and documentation that helped forge the company’s in-house capabilities to design and fabricate its own hydronic systems and equipment skids.

4

2013-2016

4-7

Freelance | TO CA

3D CAD / Graphics Designer

- Collaborated in different projects with the George Brown College’s Research & Innovation lab by providing them with CAD, CG images and illustrations of the researched subjects and their applications.

3

2011-2013

3-7

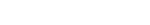

Rexelectric C.A. | VE

Co-owner / Manager

- Developed a catalog of products of 150+ pages and 1,158 items that were sent to all regular and potential customers along an eCommerce website that together doubled sales in the first month of launch.

- Designed the layout of the offices, store, and warehouse, built most of the furniture and displays, and (single-handedly) installed all the electrical wiring and lighting, cutting the initial start-up budget by 40%.

2

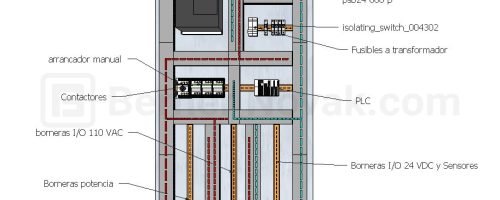

▲ 2010-2013

2-7

Rexelca C.A. | VE

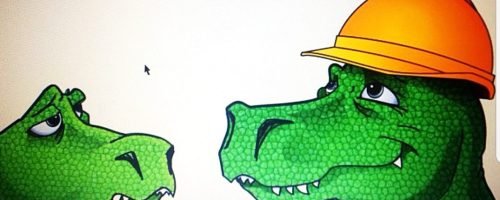

Electrical Control Panel Designer & Shop Manager

- Introduced 3D CAD design and simulation into the development process of the electrical control panels that allowed to digitally simulate the layout, wiring, equipment, fabrication, and assembly of the panels even before purchasing the first component, reducing costs, and making the process 60% faster.

- Optimized the panel fabrication shop, standardized materials and fabrication techniques that guaranteed high-quality products while expediting the fabrication, testing and delivery processes.

1

2008-2010 ▲

1-7

Rexelca C.A. | VE

Sales Representative

- Created and executed a marketing strategy that included a corporate rebranding, website, client database, uniforms, print and digital ads, resulting in a significant increase of the company’s market share in the region for the products I was hired to sell and for all the products and services the company offered.

Education

Post-secondary education

Seneca College - School of Electronics & Mechanical Engineering Technology

2014 - 2017

Mechanical Engineering Technologist Diploma - Industrial Design (MIT)

2014 - 2017

Seneca College - School of Electronics & Mechanical Engineering Technology

2014 - 2016

Mechanical Engineering Technician Diploma - Tool & Die Design (MATD)

2014 - 2016

Seneca College - School of Electronics & Mechanical Engineering Technology

2014 - 2015

Mechanical Techniques Apprenticeship Certificate - General Machinist (MATT)

2014 - 2015

ISUM

ISUM - Instituto Superior Universitario de Mercadotecnia

2001 - 2004 Venezuela

T.S.U. Marketing & Advertisement (6 sem.)

2001 - 2004

Certificates

Formal certified training

Certified Solidworks Associate in Mechanical Design (CSWA)

Dassault Systèmes

Issuing authority: Dassault Systèmes

Issued: May 2018

No Expiration Date

Credential ID:

C-3MJMW89NJ8

Workplace Hazardous Materials Information System (WHMIS 2015)

OSG

Issuing authority: Occupational Safety Group

Issued: May 2018

Expires: May 2021

Safe Operation of an Aerial Work Platform (Scissor Lift)

OSG

Issuing authority: Occupational Safety Group

Issued: Jun 2019

Expires: May 2022

Device: Scissor Lift

Fuel source: Electric

Working at Heights – Fall Protection

MSA

Issuing authority: MSA The Safety Company

2021

Lockout/Tagout Training

OSG

Issuing authority: Occupational Safety Group

Issued: Apr 2019

Expires: Mar 2022

Ladder Safety Training

OSG

Issuing authority: Occupational Safety Group

Issued: Apr 2019

Expires: Mar 2022

Ozone Depletion Prevention Certification

HRAI

Issuing authority: Heating, Refrigeration and Air Conditioning Institute of Canada

Issued: Jun 2019

Expires: Jun 2024

Valid only with previous employer

Standard First Aid, CPR and AED

Canadian Red Cross

Issuing authority: Canadian Red Cross

Issued: Jul 2020

Expires: Jul 2023

Credential: ID 101797889

Working at Heights – Fall Protection

Relevant Skills & Interests

Relevant Skills

- Bilingual (English & Spanish)

- Proficient in metric & imperial units

- Background in Industrial Automation and Manufacturing Processes Control

- Proficient in Microsoft Office (Excel, Word, PowerPoint, Sharepoint & Visio)

- Bilingual (English & Spanish)

- Proficient in SI/Metric and Imperial Units

- Industrial Automation and Manufacturing Processes Control

- Proficient in Microsoft Office (Excel, Word, PowerPoint, Sharepoint & Visio)

- Marketing, Advertisement & Sales

Basic Knowledge of

- CNC Machining, G-Code programming, CAM, EDM & CMM

- 3D Printing (PLA & ABS)

- Manufacturing Processes (Paper, Plastic, Metal & Food Industry)

- Electrical & Electronics, PCB’s, Soldering, and Breadboard prototyping

- Programming (JavaScript, Arduino, HTML5, and LaTeX)

- CNC Machining, G-Code programming, CAM, EDM & CMM

- Finite Element Analysis (FEA) in Solidworks

- Additive Manufacturing (3D Printing: PLA & ABS)

- Manufacturing Processes (Paper, Plastic, Metal & Food industry)

- Electrical & Electronics, PCB's, Soldering, Breadboard prototyping

- Programming (JavaScript, Arduino's C++, HTML5, and LaTeX)

Hobbies & Interests

- Physics, Astrophysics & Chemistry

- Indoor Gardening & Hydroponics Systems

- Playing Acoustic Guitar and Drums

- Woodworking

- Augmented Reality (AR), Wearable Tech., Transhumanism

- DIY Home Automation (IofT)

- Physics, Astrophysics & Chemistry

- Gardening / Hydroponic Systems

- Augmented & Virtual Reality

- Wearable Tech. & Transhumanism

- Woodworking (DIY)

- DIY Home Automation (IofT)